Safety Policy

Safety Policy

We’re making our products at our GMP certified factory, recognized

by the JIHFS.

Aishitoto’s products are manufactured and managed by our GMP certified factory, which was recognized by the JIHFS, the Japanese Institute for Health Food Standards. All procedures, including sanitary management for the staff, material storage, manufacturing, and delivery, are undergone strict examination to ensure absolute safety and avoid any potential risks before delivering to our customers.

We’re implementing the sanitary management based on the HACCP systems, suggested by the Ministry of Health, Labor and Welfare in Japan.

We are implementing the management system based on the criteria of HACCP, which is stipulated by the Ministry of Health, Labor, and Welfare in all manufacturing processes in our factories and restaurants.

Sanitary Management System

Sanitary Management System

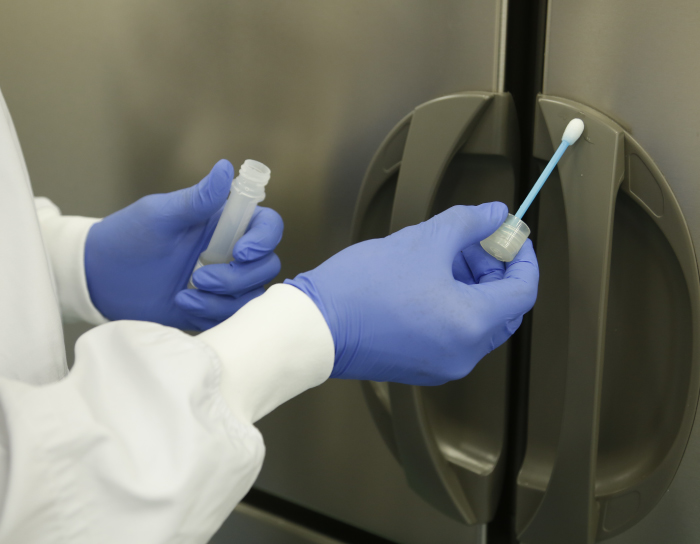

We’re implementing the regular bacterial examination.

We’re dedicated to maintaining the sanitation in our factories through the bacterial wipe test conducted by the organization recognized by the Ministry of Agriculture, Forest and Fisheries at least twice a year.

We’re implementing a different sanitary management system to deal with the seasonal change in humidity and temperature.

In-company Sessions

In-company Sessions

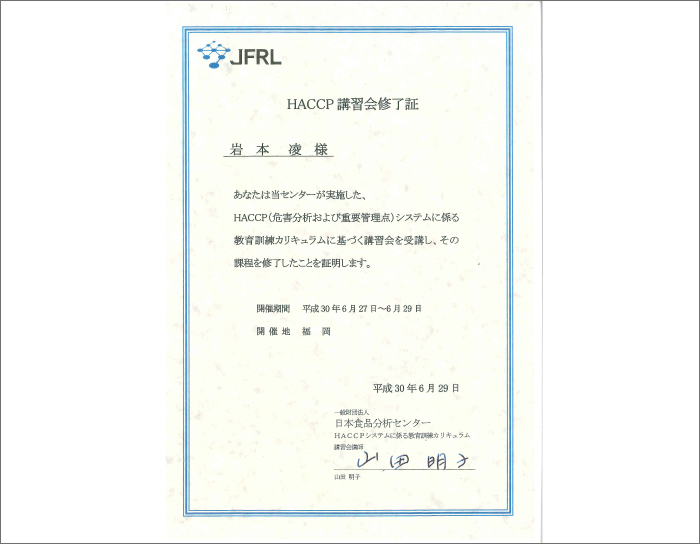

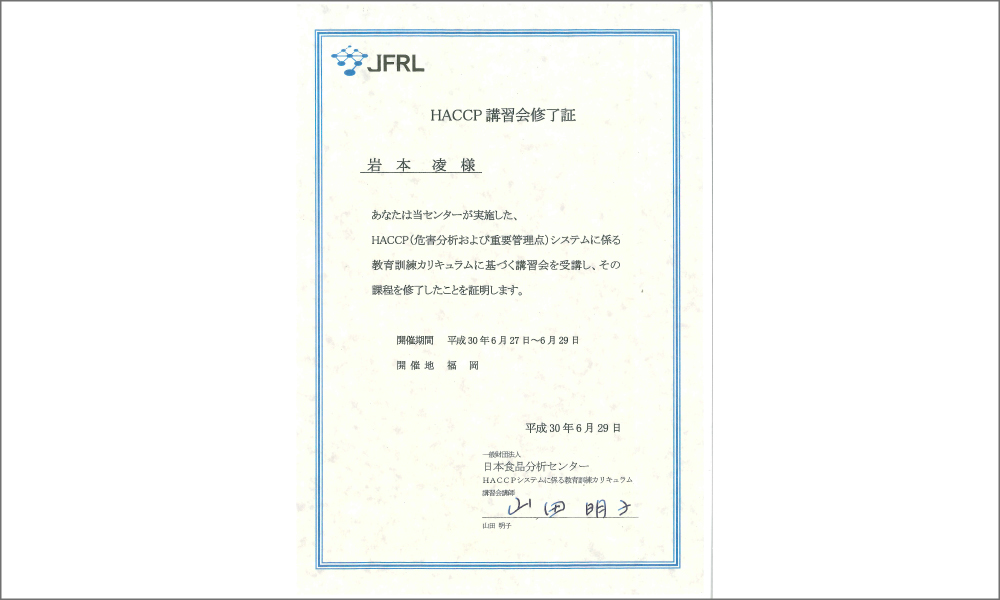

We’re participating in a regular sanitary lecture related to food sanitation.

All employees dealing with food are requested to participate in regular sanitary lectures held by the organization recognized by the Ministry of Agriculture, Forest and Fisheries. We’re organizing the sanitary management system and making products based on what we learn from the lectures.